OPERATIONS EXCELLENCE

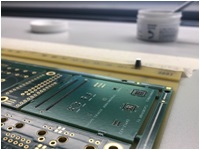

SMT Boards reflow process at E-NOTEX

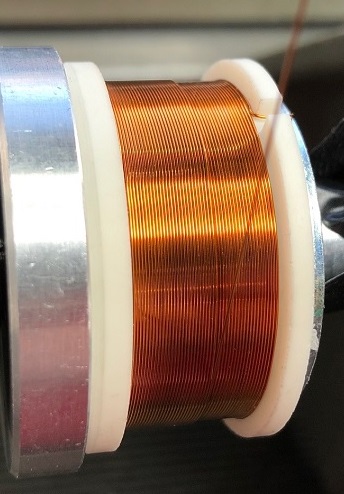

Sensor Winding at E-NOTEX

To obtain the best quality for its products and to face effectively any specific request or problem from steel plant, E-NOTEX is manufacturing in-house every critical components of its solutions.

E-NOTEX is also conducting an exhaustive testing procedure for every single product shipped to its customers, using dedicated automated test benches able to verify products specifications.

E-NOTEX highly care about customers and partners requests. E-NOTEX commits to reply or at least propose an action plan within 2 working day

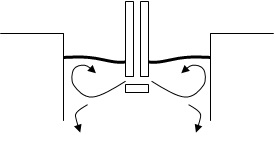

Mould Test Bench for Sensors QA Tests

INNOVATION

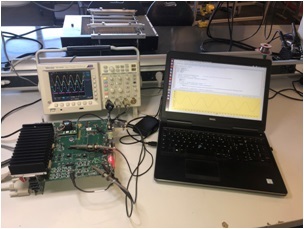

HW/SW Development

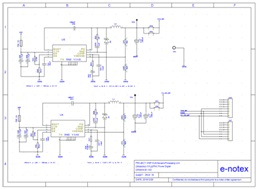

Electronic CAD

To obtain the best performances for its products and to face effectively any specific request or problem from steel plant, E-NOTEX is engineering in-house every critical components of its solutions.

E-NOTEX background includes Electro-Magnetism, Analog and Digital Electronics, Micro-Processors, Materials & Ceramics, Mechanical Construction , Metallurgy and Casting, Automatic Control, Artificial Intelligence, Mechatronics ... applied to the control of continuous casting moulds.

To develop the next generations of mould meniscus monitoring devices, E-NOTEX is using advanced dedicated tools like the LMB Liquid Metal Bench, capable to run casting simulations with either water and liquid metal.

To know more about E-NOTEX R&D program, feel free to contact us.

LMB Liquid Metal Bench